Understanding hop analysis is key to producing beer of consistent quality. Hops are a natural ingredient produced by a highly specialised horticultural system in temperate regions around the world, which means they are subject to seasonal and lot-by-lot variations. Hop analysis gives brewers the opportunity to optimise their process to achieve consistency and efficiency.

This information is intended to be a high-level practical introduction to interpreting hop analyses, and their relationship with brewing performance and beer quality. It will not explore the hop production process or how these parameters are controlled by the hop suppliers.

Hop requirements in the brewery

The basic attributes of hops should meet the following requirements:

- Normal colour, specifications, flavour and aroma

- Intact and appropriate packaging and product type

- Accurate labelling as to variety, origin, production date and bittering potential

- Free from contamination and safe for use in beer production

Product types

Hop suppliers typically provide certificates of analysis (CoAs) for dried whole hop cones or hop pellets, but they can also provide CoAs for alternate product types upon request. For instance, green hops are available during harvest, have a very short-shelf life, and typically make up a minor component of the annual hop requirement for a brewery.

Dried whole hop cones are the most natural, unprocessed product type, and can be used to form a filter bed when straining the boiled wort or dry hopping. They are picked, dried and pressed into bales, which can be broken down into smaller, vacuum sealed quantities.

Hop pellets are dried whole hop cones that have been milled into powder and pressed through a pellet die. Different milling technology allows for the production of various pellet types. The most common are T90 (standard), T45 (lupulin enriched) and pre-isomerised.

Certificates of analysis and specifications

Brewers can use CoAs to anticipate process changes required to achieve consistent brewing results, and to verify compliance with hop specifications.

Most product types will be supplied in sealed, oxygen barrier laminated foils that have been back-flushed with inert gas (carbon dioxide or nitrogen) and packed in cardboard cartons.

As a minimum, each carton should be labelled with variety, producer, crop year, production date, batch identification numbers, product type, net weight and bittering potential (alpha acid contents and analysis method). There is no standardisation of CoA information. In their most basic form a CoA will cover the same information as the carton labels, but some more detailed CoAs may include additional information such as essential oil content, moisture content or agricultural chemical residue reporting.

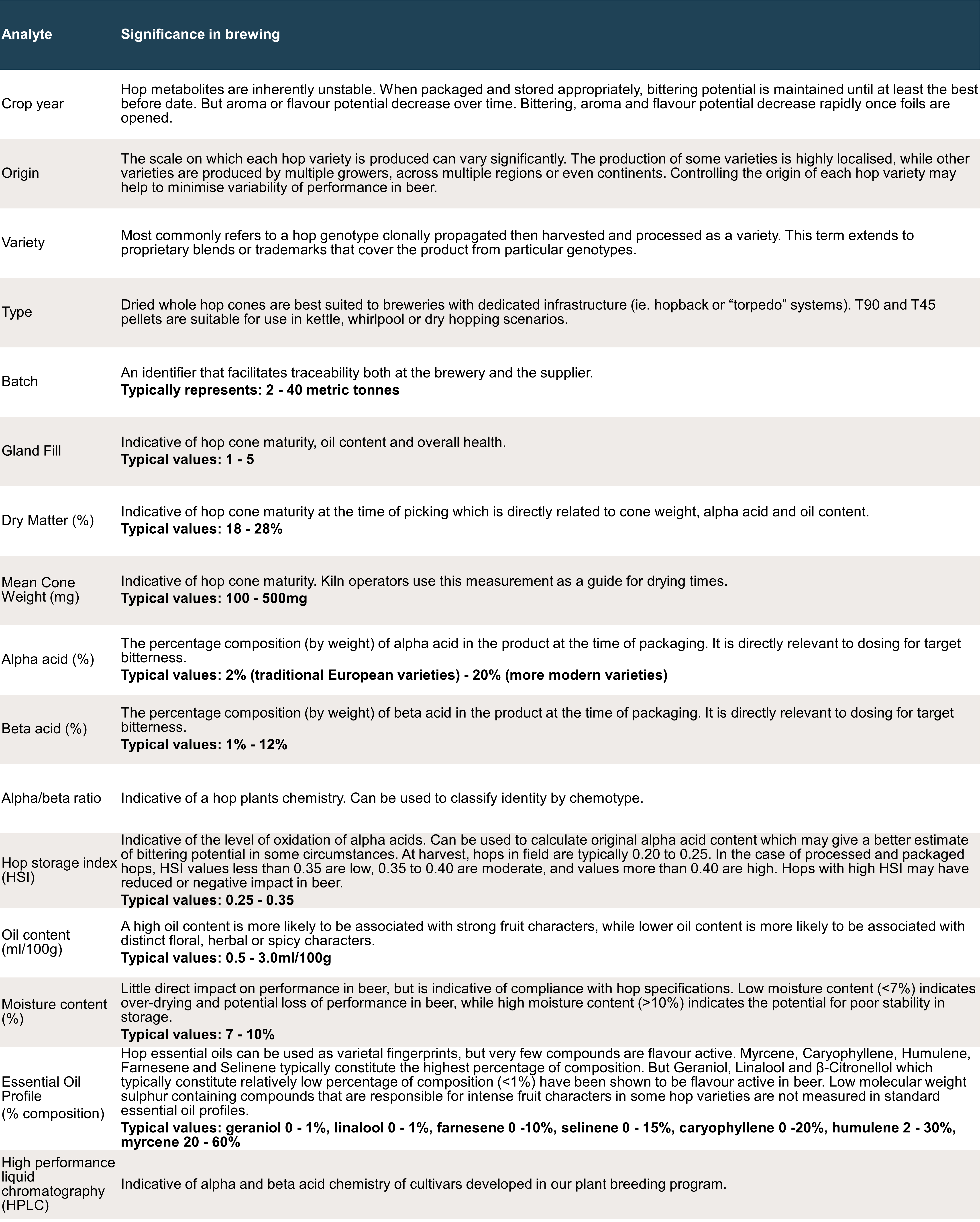

Typical hop analyses and their significance

Drivers of variability in analytical hop quality outcomes

Accuracy and inter-laboratory error in hop analysis

When assessing compliance with hop specifications, it is important to note many of the methods published by European Brewery Convention (EBC) and American Society of Brewing Chemists (ASBC) for measuring the above analytes have high standard deviations and inter-laboratory error. The ASBC run an international check sample service that is focused on the analysis of bitter acids using titration, spectrophotometry and high performance liquid chromatography (HPLC). There are currently no inter-laboratory comparisons made for determination of moisture content, oil content or essential oil profiles.

Food safety issues

Hops that are used in brewing are a food ingredient. This means producers are required to ensure all typical food safety requirements are met. Suppliers should be able to provide allergen and residue statements.

Beyond CoAs

Hop CoAs and label information describe the hops at the time of packaging. Chemical changes that affect performance in beer may occur if the hops are transported, stored and/or handled improperly at any stage of the supply chain.